Shingled Mono Solar Panel

namkoo solar

namkoo solar

HJT Shingled Solar Panel Mono Solar Panel 560w Pv Module

Shingled Mono Solar Panel Process Description:

Stacked tile technology is a technology where the cells are sliced and then welded into strings using a special conductive adhesive material.

The cells are connected in a front-to-back stack, with no metal grid lines on the surface and no gaps between cells, making full use of the available surface area of the module.

This reduces the wire loss associated with conventional metal grids and therefore significantly increases the module's conversion efficiency.

In terms of reliability, the traditional metal grid connection is a wire connection.

In contrast, stacked modules are surface-connected, thus improving the cell-to-cell connection force and making the modules more reliable.

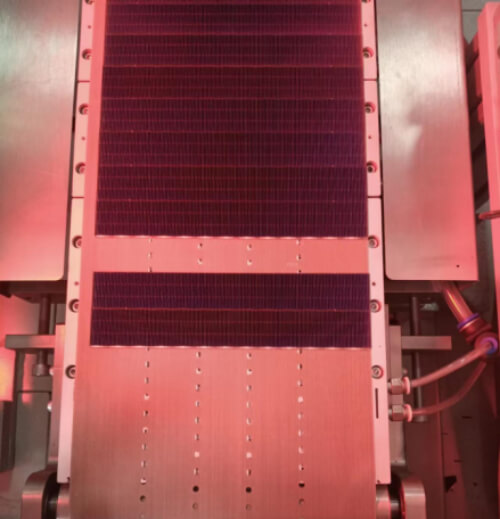

Stacked tile string welding process

Shingled Mono Solar Panel Advantages and disadvantages

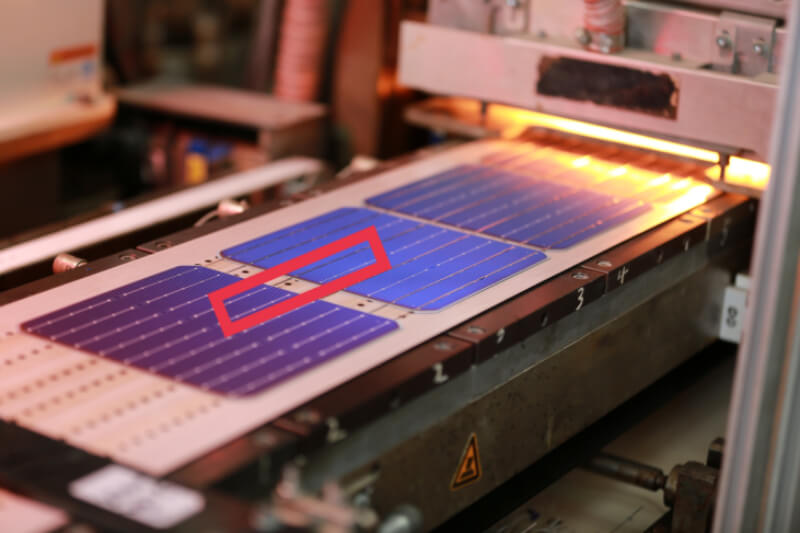

Conventional mono-crystalline modules String welding process

Advantages:

1.1) The use of conductive adhesive string welding cells, the overall cell resistance to hidden cracking effect is better, in short, the theoretical life is longer, the premise of the same power station capacity, winter power generation and rain, snow and other bad weather conditions, power generation data is higher;

1.2) The use of high-density packaging technology eliminates cell spacing and increases the effective light receiving area of a single module;

1.3) It can effectively reduce the effect of hot plate effect and module operating temperature, and has stronger anti-fading performance, which makes the power generation data more optimistic under practical application scenarios

Disadvantages:

Stacked tile process belongs to the emerging process, currently in the market application of the overall time 5-6 years, there is no longer use of years of intuitive comparison, such as the traditional single polycrystalline components, to date the longest application of the power station has exceeded 40 years, will make its 25-year life warranty more convincing, but the stacked tile process components, the current application of the short years, so there is no actual data to do the basis to say that its life than the traditional long

Our strengths:

We have a separate cell testing workshop, where we test and sort cells in four areas: cell efficiency/power/colour/EL, etc.

Purpose of cell sorting? (100 % to detection rate):

1. efficiency & power sorting: with a power difference of 0.1W/cell as the standard, the cells will be differentiated, which can ensure that the power error of the finished solar panels is reduced within a controllable range; for example, before another brand of panels in our company to do testing, with 480W power sales to you, but the actual power is only 442W and 427W, there are two problems here, power shortage is one problem The other is that the power difference between the two panels is 15W, whereas if we have sorted the cells, the power of the finished product can basically be controlled within 5W per day, and there will not be such a big power difference

2. Colours: The machine sorts the cells in the form of light dots (1-9 for 9 colours) to avoid colour differences to a large extent.

3. EL: EL inspection is a very important test to avoid or control the occurrence of hidden cracks in the finished product, the existence of hidden cracks will affect the life of the panel